Explore the unique specifications, quality, and processing methods that make Black Crystal graphite exceptional.

Graphite Specifications

Purity

Up to 99.995% carbon purity. This high level of purity is essential for demanding industrial and energy applications. It ensures top-notch performance in energy storage systems, such as lithium-ion batteries, and in thermal management.

Flake Size

We offer jumbo and super jumbo flakes, ideal for high-performance applications. Larger flakes improve conductivity and expandability. These properties are vital for advanced technologies, including lithium-ion batteries and industrial foils.

Applications

Our graphite is versatile and supports a wide range of industries. From electric vehicles (EVs) to fireproof materials, our graphite is key to innovative, cutting-edge technologies.

Unmatched Performance & Efficiency

Premium Flake Yield 95%

Marketable Tailings

Utilization 100%

Carbon Recovery Efficiency 97%

Quality Tailings Material 100%

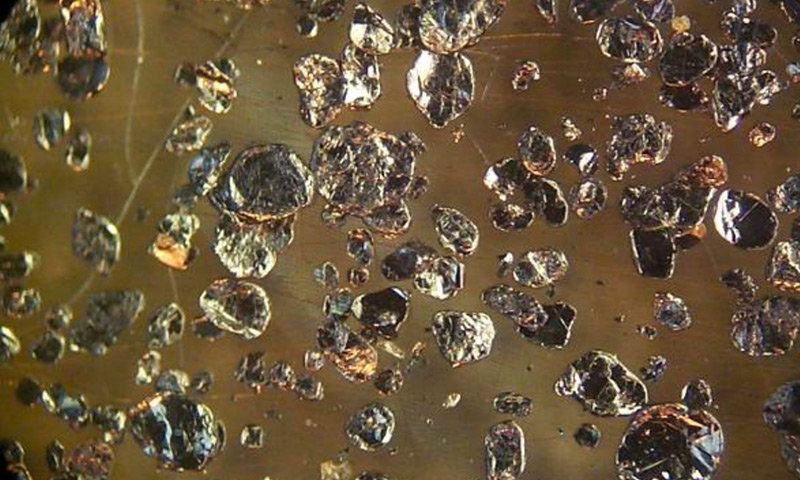

(Macro Zoom)

Purity Archived 99%

Production-Ready Status 100%

Extraction

The graphite is extracted from a sand-like host material. This makes it easier to separate impurities and achieve high purity.

Purification

Additional processing steps further purify the graphite, bringing it to 99.995% purity. This meets the highest industrial standards.

Flotation

We use a multi-stage flotation process to consistently produce a 95+% carbon concentrate. This process is efficient across various flake sizes.

Marketable Byproducts

Tailings such as sand and gravel are fully marketable. These byproducts are used in golf courses, aggregates, and concrete.

How It's Processed

Black Crystal graphite is processed using simple, eco-friendly methods. We maintain high-purity levels while minimizing environmental impact.

Quality You Can Trust

Black Crystal graphite is known for its superior quality, purity, and performance. Rigorous testing and advanced processing methods back every batch we produce.

Ready to Learn More?

Dive deeper into the specifications and opportunities of Black Crystal graphite.